Growth by Technology

Innovation +

Reliability

= Solution

TRUE ALL-ROUNDERS

Adhesive tapes from tesa are true all-rounders: At home or in the office, their primary job is to fasten and hang, seal and insulate, repair and renovate. However, industry presents completely different requirements: There, adhesive tapes have to ensure that heavy components are bonded for decades, they need to conduct or shield from electricity, act as shock absorbers, aid light and heat management, be flame-retardant, be removable with no residue, and much more.

Ideas for the car of tomorrow

This explains why tesa creates around 100 new adhesive solutions every year – many of them for the automotive industry, which is rapidly advancing with new applications, particularly in the e-mobility segment. And this is because adhesive solutions are often lighter and cheaper than other fastening options. They also meet the highest standards in terms of appearance, safety and flexibility.

The team works with many international automotive manufacturers and their suppliers. There are now around 1,000 different adhesive solutions from tesa for industrial applications in the automotive sector on the market. And that number is steadily growing, since their many advantages help to turn concepts for the mobility of the future into a reality.

No limits to design and layout

Adhesive solutions from tesa eliminate the need for mechanical connections when mounting displays and touchscreens. The optically clear adhesive tapes also allow multiple layers of a display device to be bonded without affecting brilliance and brightness.

Glued and assembled

A fully automated assembly line for battery packs gives the automotive industry everything it needs from a single source. With the tesa® ACXplus 76730 Box Seal, tesa adds a new flexible adhesive application that securely and completely seals battery packs, and enables touch-ups and removal of parts.

More freedom for displays and touchscreens

One example of this is in the increasing number of infotainment and assistance systems in cars: Acrylic foams from the tesa® ACXplus range do more than eliminate the need for mechanical connections when mounting displays and touchscreens. They can also compensate for manufacturing tolerances of individual components and securely bond a wide variety of materials. And, despite their strong and durable adhesive strength, they can be easily removed, allowing electronic instrument panels to be replaced and recycled.

To ensure that the image quality of displays and touchscreens is not impaired, tesa has also developed optically clear adhesive tapes especially for the automotive industry: With these tapes, individual layers of a display device can be permanently and securely bonded without affecting brilliance and brightness. Integrated curved displays can also be easily adhered.

Battery packs: fully automated assembly

Innovative adhesive solutions are also increasingly used in battery manufacturing – for assembly, insulation, thermal management, and protection. In cooperation with other partners, tesa recently launched a fully automated assembly line for battery packs, the tesa® ACXplus 76730 Box Seal. This solution gives automotive manufacturers everything they need for bonding and assembling battery packs from a single source.

Thanks to its adaptability and flexibility, the adhesive solution developed by tesa can be applied to both battery packs with lids and battery packs mounted directly on the vehicle underbody. tesa® ACXplus 76730 Box Seal achieves 100% sealing, requires no curing time, and enables easy-to-use, automated application. In addition, the innovative product allows the battery pack lid to be removed for touch-ups and enables easier recycling of battery systems.

“tesa has been a leading provider of adhesive solutions to the electronics industry for more than 15 years. We are building on this expertise to develop cutting-edge products for the automotive market in the field of displays and sensors, such as removable adhesive tapes that enable the repair and recycling of components, enabling our customers achieve greater sustainability. In addition, we see great potential and business growth in e-mobility: It opens up many exciting prospects for tesa.”

David Caro

Corporate Vice President Automotive at tesa

Tapes that protect from corrosion

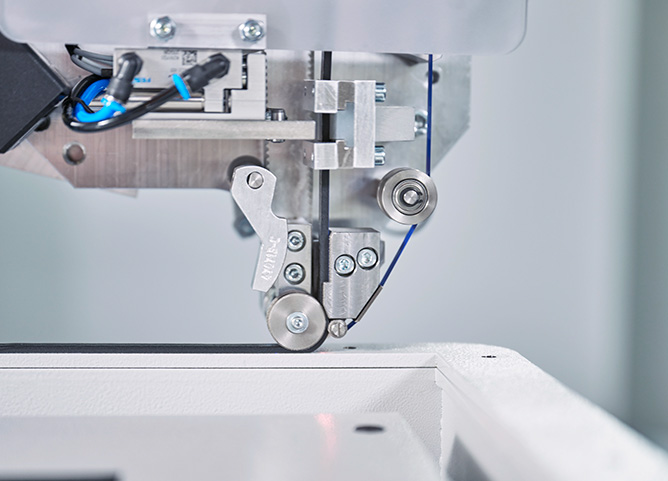

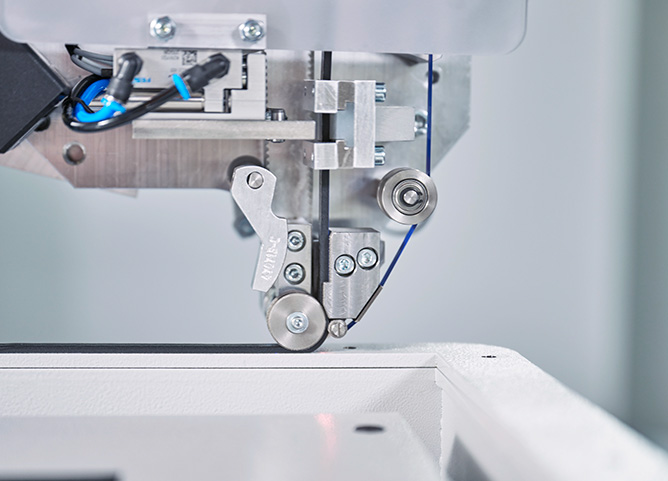

tesa has also developed a forward-looking solution for the automotive industry with the tesa® EfficienSeal automatic application unit. This is a fully automatic solution that uses adhesive pads to seal holes in the vehicle body. The holes required for the painting process are often still closed manually with plastic plugs to protect the vehicle body from corrosion.

Not only does the system developed by tesa make this a much faster process, it also uses robots to position the adhesive pads with millimeter precision, sealing the holes completely and permanently. This prevents unhealthy and monotonous steps and significantly reduces the risk of missing or incorrectly inserted plugs. Another major advantage is that adhesive pads are much lighter than plastic plugs and thereby contribute to a lower overall vehicle weight.

All-rounders with a great future

The rise in e-mobility opens up a wide range of opportunities and prospects for tesa. This calls for new technologies and materials that do more than reduce a vehicle’s weight and attach parts and components quickly, efficiently, and permanently. They also need to meet the new requirements resulting from an electric drive, such as bonding battery cells, fireproof lining battery packs, or insulating electronic components. Adhesive solutions can do all this and much more. Their status as all-rounders means that their importance in the automotive industry will continue to grow in the coming years.